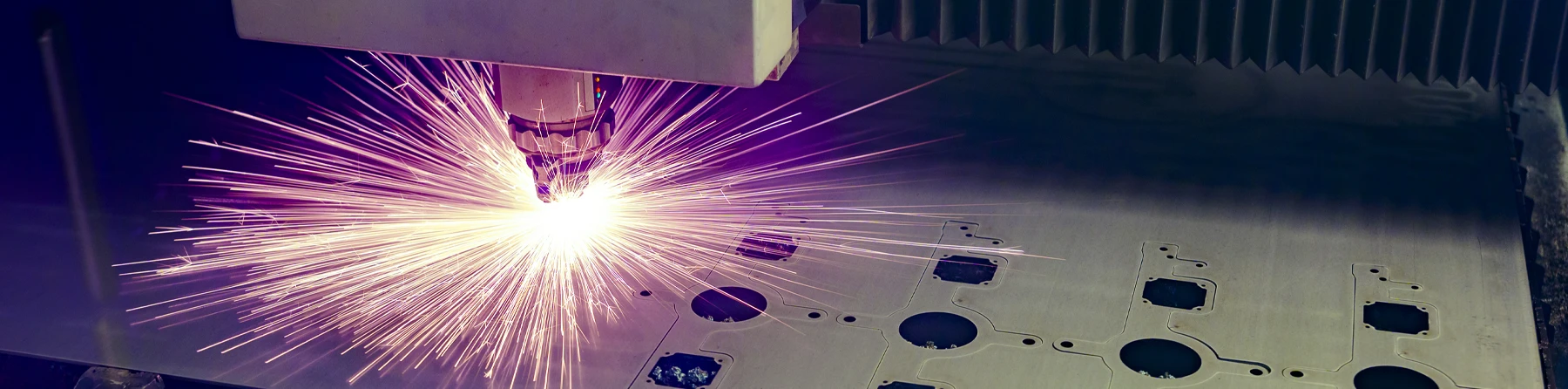

Laser cutting Brescia

2D laser cutting (two-dimensional) allows to operate with precision and speed, performing even very complex geometries, sometimes not achievable by moulding or by other sheet metal processing. Our machines allow us to process small and large batches according to the needs of the customer, thus ensuring flexibility and much lower costs compared to those of traditional processing. Your design will quickly take form with our support in the design phase.

Cutting-edge machinery for flawless processing

To perform 2D laser cutting we have cutting-edge machinery, advanced technology and latest generation equipment:

- TruLaser 3030 Fiber Trumpf, working range 1500x3000 mm and automatic pallet change.

- TruLaser 3030 CO² Trumpf, working range 1500x3000 mm and automatic pallet change.

Certified quality materials

Mevar offers high quality products by treating only certified and first choice materials. For example, we use super mirror stainless steel with pvc protection for components in the sanitary sector, while for the lighting sector we use aluminum alloys with super reflective pvc.

2D laser cutting enables us to process sheets of different alloys and thicknesses:

2D laser cutting enables us to process sheets of different alloys and thicknesses:

- Iron: thickness up to 20 mm.

- Stainless steel: thickness up to 20 mm.

- Aluminium: thickness up to 15 mm.

- Brass: thickness up to 8 mm.

- Copper: thickness up to 8 mm.

- Titanium: thickness up to 8 mm.