Sheet metal machining - Moulding - Blanking

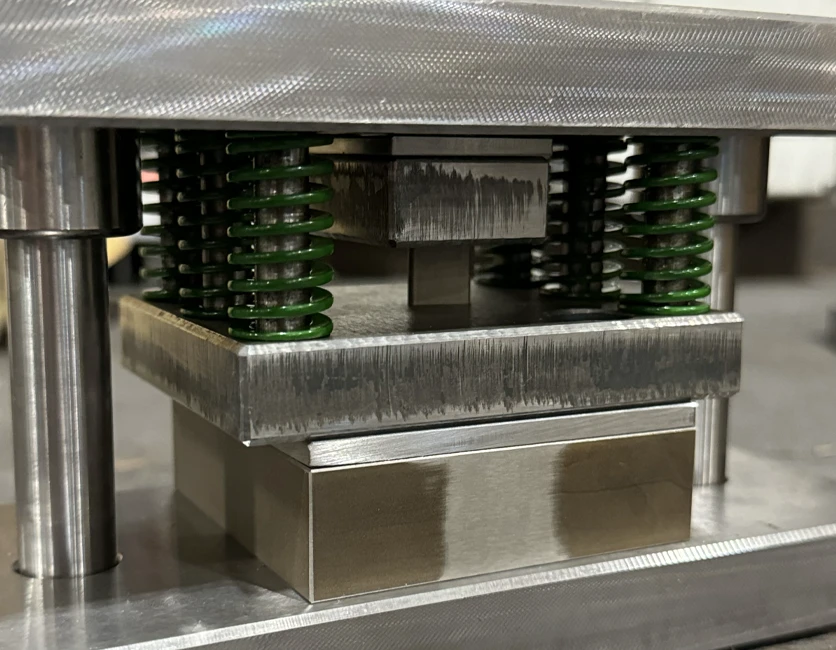

Moulding by blanking is used to cut sheets and plates on which to make shapes, holes, slots and shapes of any type. Blanking allows to shape with maximum precision also the perimeter of the part. The blanking operation consists, in fact, in pressing onto the sheet a cutting force sufficient to separate the material along the border of the cutting unit of the mould. This type of moulding is performed using a mould formed by a punch and a die that slice the sheet to obtain a shaped element as indicated by the punch (positive) and the die (negative).

Two blanking types

There are two blanking types, simple and complex.

- The first consists in the "simple" cutting process and die-cutting of the sheet metal. It must always be done skilfully to ensure evenness and to avoid possible problems.

- The second, so-called "complex", associates blanking to other mechanical processes such as bending, coining, deep drawing, thus it needs a highly detailed machine designing and equipping phase.

Mevar "optimises" blanking

Mevar knows the challenge isn't only to blank well, but also to optimise encumbrances, overcome constraints and take costs into consideration. We have learned over the years that, in order to optimise production costs for our customers, we have to implement precise blanking procedures for every different type of item, always seeking the best solution.

With the transfer blanking method (transferring) accurate finished parts are made that are characterised by the purity of the inclusions, maintaining an optimal state of the surface, verifiable by its perfect evenness.

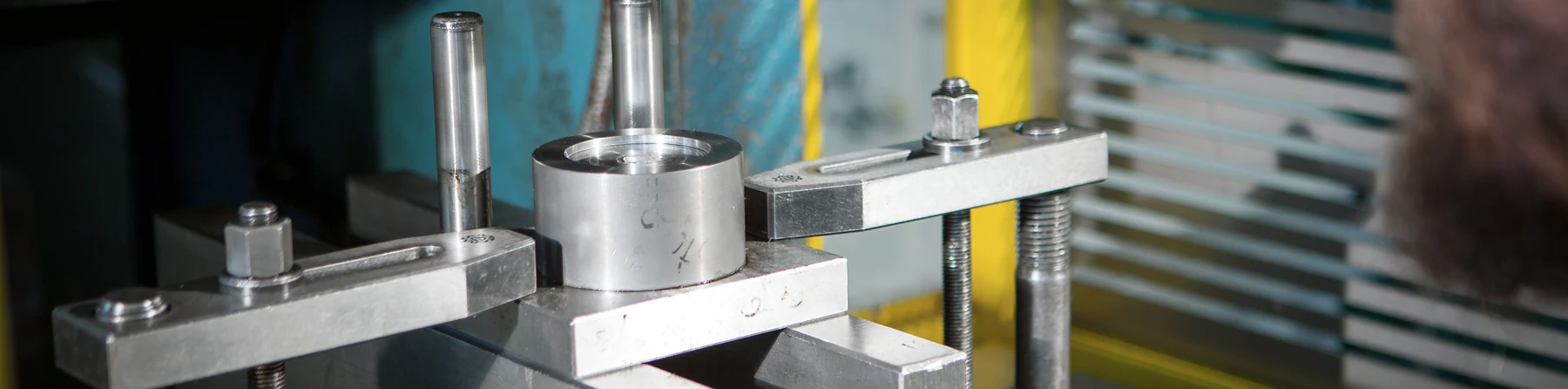

At Mevar we perform blanking using moulds that we design and manufacture in-house or by equipping our presses with your own moulds.

With the transfer blanking method (transferring) accurate finished parts are made that are characterised by the purity of the inclusions, maintaining an optimal state of the surface, verifiable by its perfect evenness.

At Mevar we perform blanking using moulds that we design and manufacture in-house or by equipping our presses with your own moulds.