Sheet metal machining - Punching

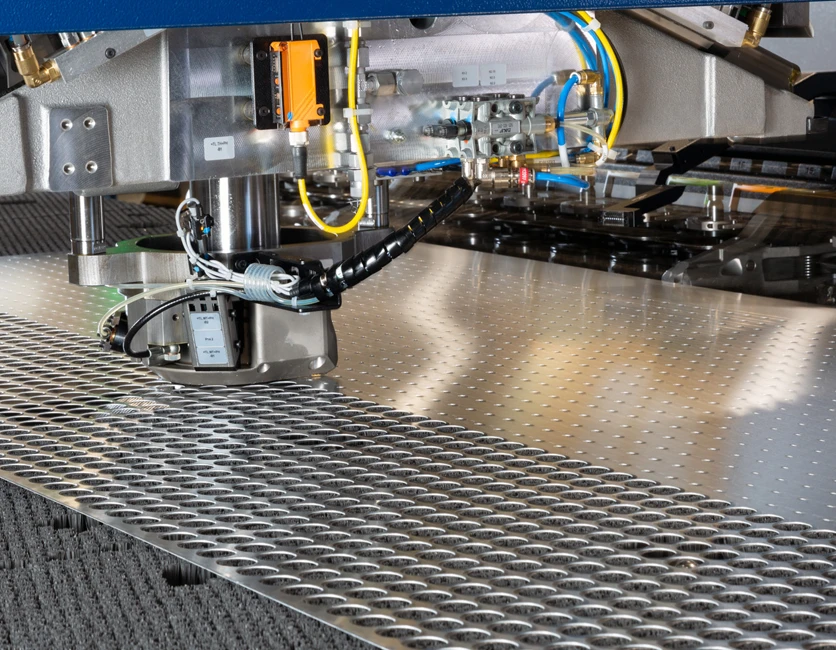

Mevar also deals with metal punching to make holes and incisions in sheet metal. Our high-performance TruPunch 1000 system allows us to be extremely competitive in terms of cost and production speed.

Sheet metal punching with special equipment

With the help of punches designed and manufactured in-house, we are able to realize a specific equipment in a short time thus avoiding to make equivalent moulds for presses. Punching equipment can perform various machining processes, such as countersinking, threading, shearing, embossing, small folds and cutting. These phases, when combined, allow the optimization of the processes, with consequent cost savings.

Equipment and processed materials

Equipment for punching system:

- n.1 TruPunch 1000 punching machine "Large size" 3000x1500 mm.

- Iron: thickness up to 5 mm.

- Stainless steel: thickness up to 3 mm.

- Aluminium: thickness up to 6 mm.

- Brass: thickness up to 6 mm.

- Titanium: thickness up to 3 mm.

- Copper: thickness up to 5 mm.

- Plexiglas: thickness up to 6 mm.