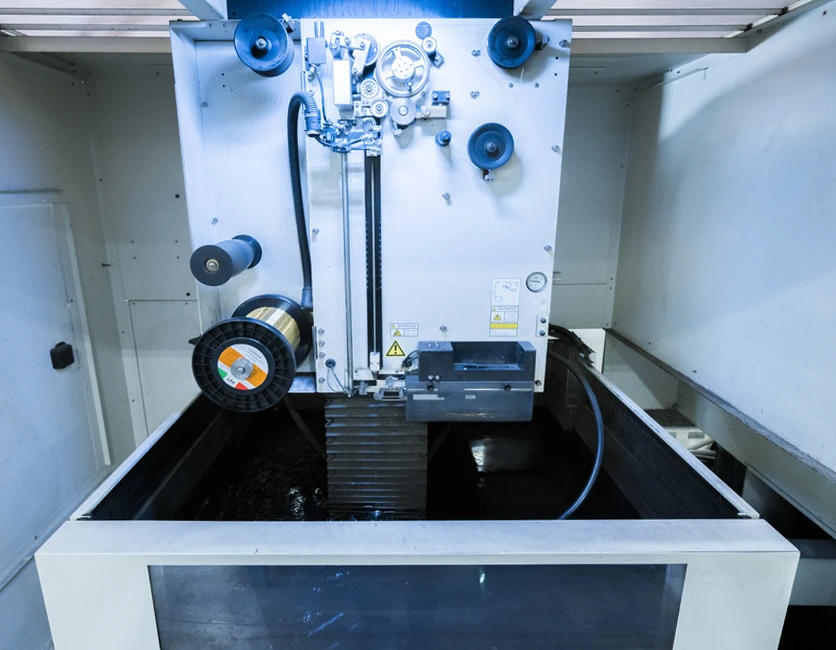

Wire electroerosion

Wire electroerosion is required to build moulds and equipment. Mevar also offers customers a third-party cutting service. Wire erosion consists in cutting a defined contour through a wire that generates electrical discharges, obtaining shapes of various sizes, but above all, ensuring compliance with minimal tolerance limits.

Elettroerosione, la tecnica ideale per tagliare metalli duri

Electroerosion is a very sophisticated technology that allows to cut any type of material, as long as it has electrical conductivity. It is particularly suitable for hard alloys, such as hardened steel, fast steel or sintered steel.

Metals electroerosion can be of three types:

Metals electroerosion can be of three types:

- Wire electroerosion.

- Die-sinking electroerosion.

- Microperforation.

The right process for complex shapes

The common denominator of all three different types of EDM is the electric current that is transformed into pulses and transferred to the metal in a bath of refrigerated insulating liquid. This technology allows to transform and obtain complex shapes, which would be impossible to achieve through other processes.

With the same technique we also perform micro-perforation operations with a specific machine that uses small tubes as electrodes. Thanks to this technology we can create holes that cannot be made with other technologies.

With the same technique we also perform micro-perforation operations with a specific machine that uses small tubes as electrodes. Thanks to this technology we can create holes that cannot be made with other technologies.