3D laser cutting

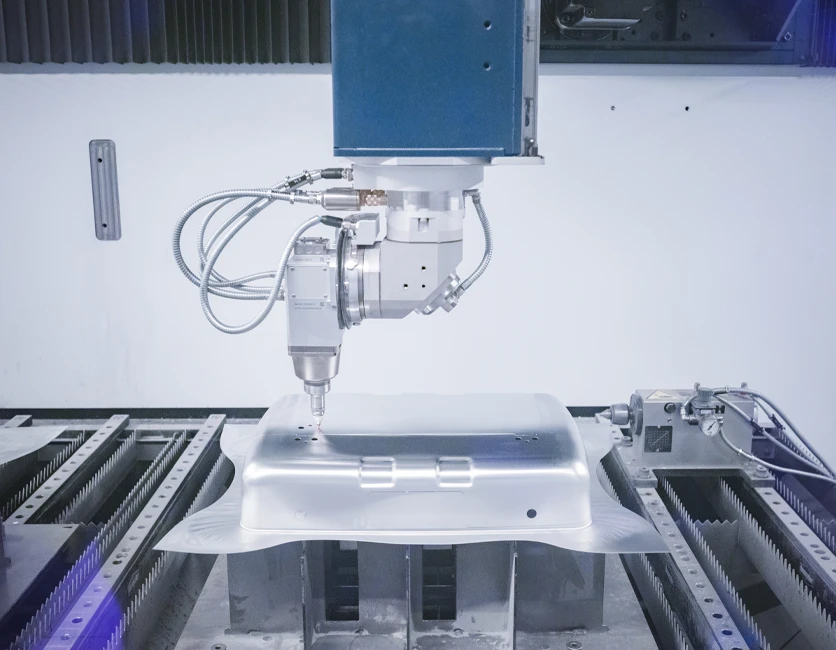

3D (three-dimensional) laser cutting is an increasingly used technology in sheet metal processing. With the help of masks, designed and manufactured in-house, it is possible to obtain cuts and holes on deep-drawn components, ensuring maximum quality and aesthetic performance in a very short time.

Advanced technology for many advantages

Our 3D laser cutting systems are very versatile and offer the possibility to produce samples, small batches or series production, thus avoiding significant costs for the production of dies or equipment, always ensuring high precision machining.

3D (three-dimensional) laser cutting equipment:

3D (three-dimensional) laser cutting equipment:

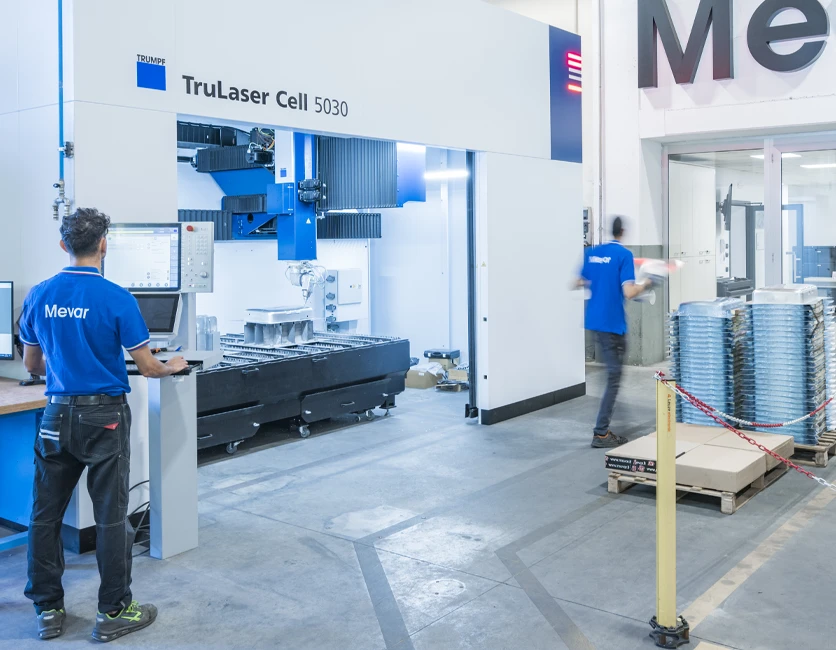

- TruLaser Cell 5030 Trumpf, working range 1500x3000 mm + mandrel Ø200 mm max.

- Fabri Gear U44 Mazak, working range 900x900 mm + mandrel Ø180 mm max.

Flawless cut and optimized time

The new TruLaser Cell 5030 guarantees an impeccable cutting quality, thus avoiding cleaning or burrs removal treatments and optimising production times. In addition, the cutting programs can be modified in a very short time, offering the customer the possibility to modify, at no additional cost, the finished product.

With the 3D laser cutting technique we can successfully process metals such as iron, aluminium, stainless steel, copper and brass.

With the 3D laser cutting technique we can successfully process metals such as iron, aluminium, stainless steel, copper and brass.