Mevar: all sheet metal processing techniques

We are a company that embodies multiple skills in the field of sheet metal processing. We offer our customers all the techniques available in the sector: prototyping, moulds design and construction, 2D and 3D laser cutting, punching, moulding through blanking, bending, deep drawing and mechanical machining of various types. We can therefore propose the most convenient type of machining according to the type of article and the quantity to be produced. For example, we recommend laser cutting for low quantities and moulding for high serial production, always with an eye on the quality of the items produced, which must be impeccable.

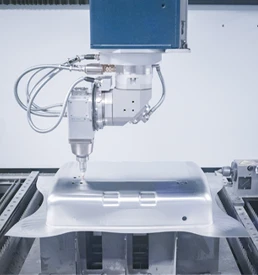

Laser cutting and welding

With the innovative laser cutting technique we process various metals such as stainless steel, iron, aluminium, brass, copper and titanium. We can perform with high precision both 2D and 3D laser cutting. We also offer tube cutting, welding and laser marking.

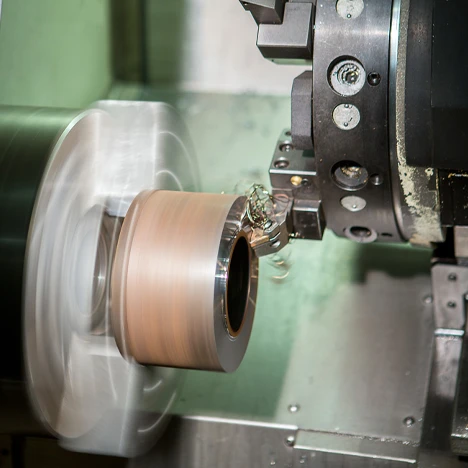

Mechanical processing

In our structured mechanical department, we manufacture or refine items with different processing techniques, typical of mechanical workshops. Below we list the main ones.

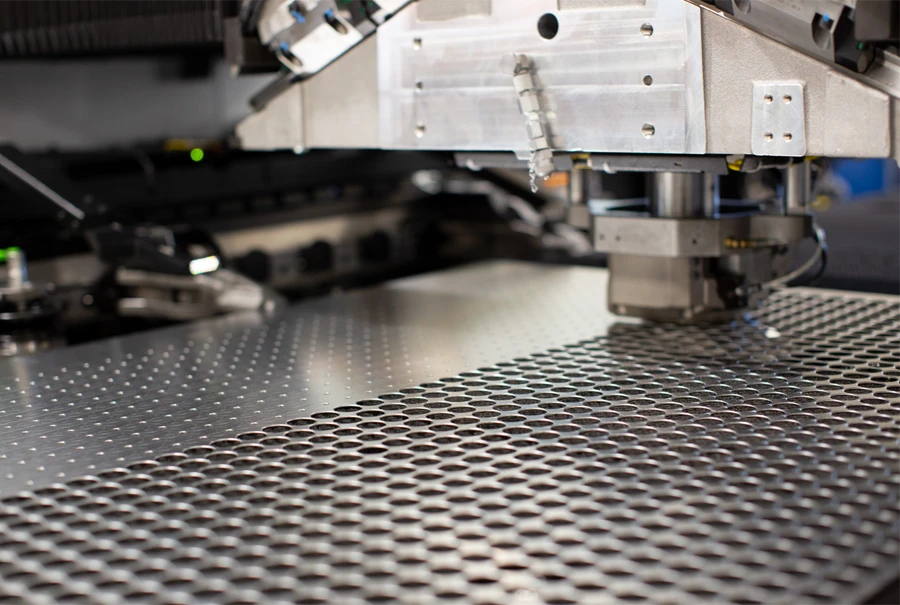

Sheet metal machining

Thanks to our complete and efficient machine park, we can perform all the classic sheet metal machining, starting from moulding that includes the techniques of blanking, deep drawing, bending, bending by mould, trimming and edging.

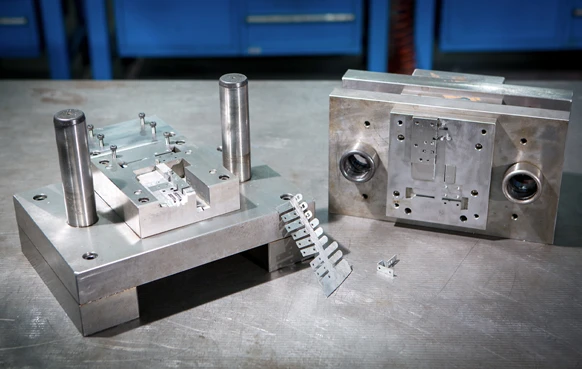

Mould building

The construction of our moulds begins with a design work that always ensures a perfect moulding. We always use the best materials and all our expertise.

Optimised production processes and certified quality since 1972

We supply any industrial sector, as well as engineers, architects, and designers who need to develop/manufacture new products or even improve existing ones. Today Mevar Srl is the main supplier for leading Italian manufacturers of lamps, housewares, home appliances, motor vehicles, and many other types of items, such as components for the automotive industry.

Our task is to give shape to ideas, resolve technical challenges, renew processes for ever more effective and competitive production, optimising time and costs.

Our task is to give shape to ideas, resolve technical challenges, renew processes for ever more effective and competitive production, optimising time and costs.

In addition to planning and designing, we cooperate with our customers in order to develop projects and research new products and components that ensure greater performance and decrease costs.

In order to offer all of these services, we boast a state-of-the-art technical office, with a metrological room specialised in prototyping and testing, at the disposal of customers for any simulations or sampling necessary to develop new ideas. This know-how has positioned us in an ever more competitive marketplace that now demands not just manufacturing capacity but also, and above all, problem-solving, innovative ideas, and growing quality.

In order to offer all of these services, we boast a state-of-the-art technical office, with a metrological room specialised in prototyping and testing, at the disposal of customers for any simulations or sampling necessary to develop new ideas. This know-how has positioned us in an ever more competitive marketplace that now demands not just manufacturing capacity but also, and above all, problem-solving, innovative ideas, and growing quality.

continue

close