Sheet metal machining - Welding

In addition to laser welding, we also perform welding operations with traditional technologies, so we have the opportunity to choose the most suitable solution according to our customer's production needs and according to the type of processing to be performed.

Automated TIG welding

We perform TIG welding with or without the addition of material, depending on the article to be produced. With the help of the CMM longitudinal welding machine we can perform automated TIG welding. This machine allows us to obtain a highly resistant weld, safeguarding the aesthetic result which is constant, beautiful and homogeneous.

Equipment and features of our automated welding plant:

Equipment and features of our automated welding plant:

- TIG CMM automatic welding machine.

- Maximum automatic length: L=600 mm.

- Workable materials: iron, stainless steel and titanium.

- Thickness: from 0,5 mm to 1,5 mm.

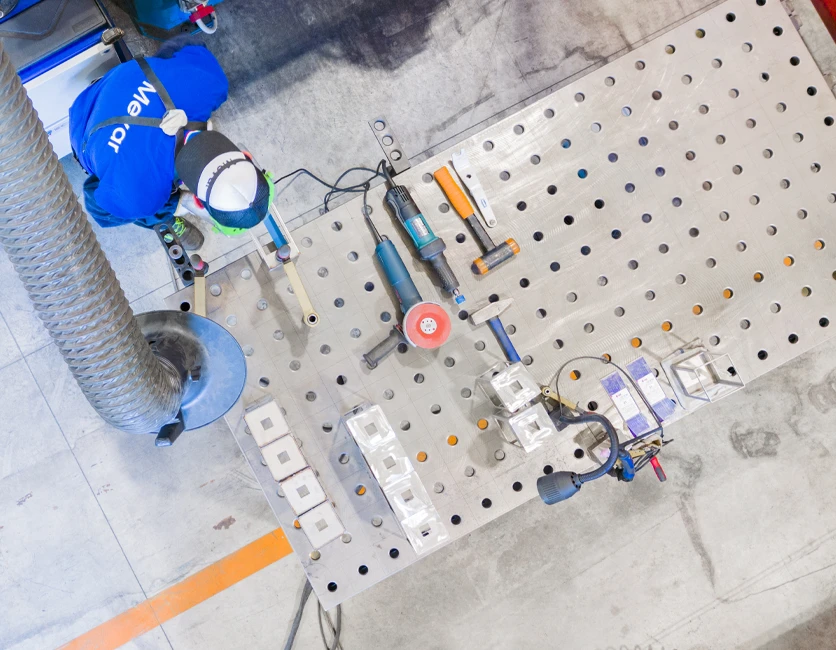

Manual welding

With the DEMMELER 3D welding table, we can meet all TIG, MIG/MAG and wire welding requirements. The quick fastening system ensures optimum surface tightening, resulting in perfect adhesion of the welding points. These types of traditional welding are still convenient and suitable for some types of metal processing, so we keep them among our services.

Electrode/spot welding

We also perform electrode/spot welding, a technology with which we can fix sheet metal components, nuts or bolts with the help of spot welders.

Equipment for electrode/spot welding:

Equipment for electrode/spot welding:

- CEA column spot welder.

Additional processes

In order to provide a complete service, after the welding processes we can also perform some finishing operations such as:

- Pickling.

- Grinding.

- Sandblasting.

- Satin finish/brushing.

- Polishing.