Sheet metal machining - Sheet metal turning

We have implemented sheet metal turning in order to optimize the timing in the production of deep-drawn products, with a consequent reduction in machining costs and, in particular, the zeroing of the initial investment for the dies.

Time and cost optimization for deep-drawn products

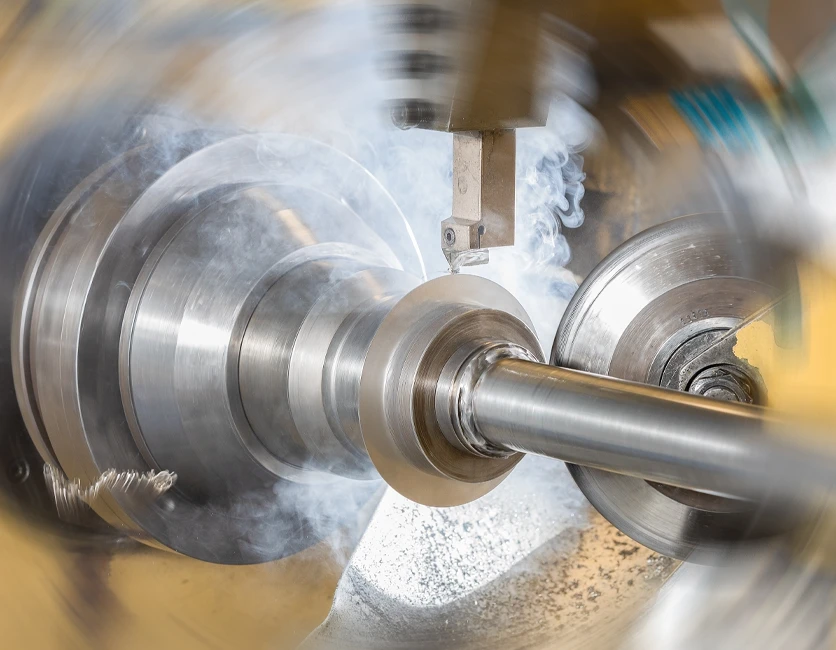

Sheet metal turning is a working process that allows to deep-draw components without the use of moulds. For the sheet metal turning process, we use an equipment designed and manufactured in-house, which can be obtained in a short time and above all at very low costs compared to those of the equivalent moulds for presses.

Equipment for sheet turning:

Equipment for sheet turning:

- n.1 Giotto 400 NOVA SIDERA lathe.

Flexible technology for different materials

Sheet metal turning is very flexible, recommended for prototypes, small batches or series production. Our design department, analyzing material, lots and budget, is able to advise the customer on the best production process.

Through self-learning cnc machines, we manufacture articles in stainless steel, iron, aluminum, titanium, copper and brass. This technology allows to offer a productive alternative to the classic moulding, reducing time and costs.

Through self-learning cnc machines, we manufacture articles in stainless steel, iron, aluminum, titanium, copper and brass. This technology allows to offer a productive alternative to the classic moulding, reducing time and costs.